WellAware - Industrial IoT Machine Learning

Client: WellAware

Year: 2025

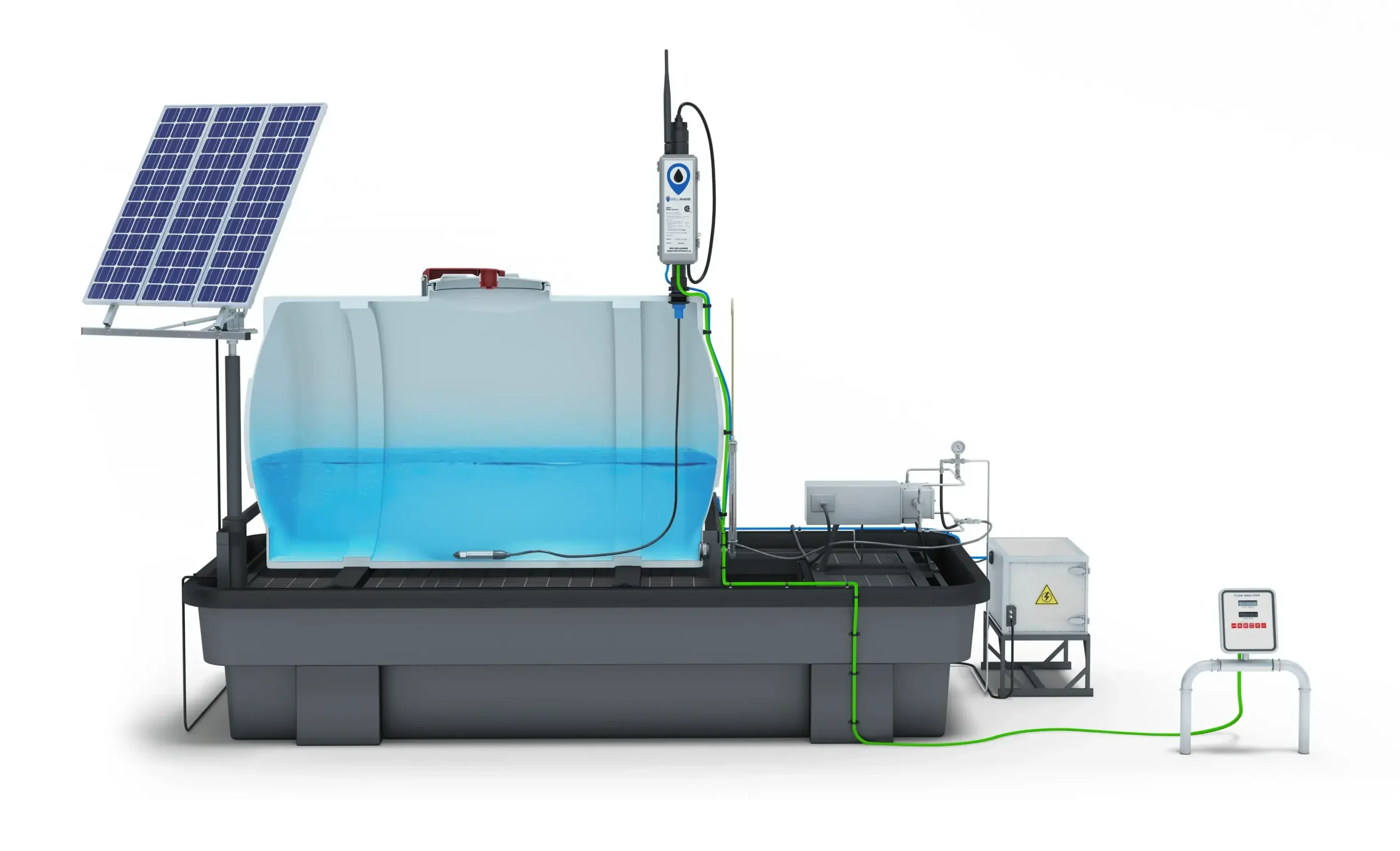

Advanced ML for predictive & reactive maintenance in industrial IoT, optimizing oil & gas, water, and chemical monitoring operations.

Technologies Used

Project Gallery

Project Overview

WellAware specializes in industrial automation and data analytics solutions, primarily for the oil and gas industry. My collaboration focused on enhancing their predictive and reactive maintenance capabilities. I developed a traditional machine learning solution that processes sensor data from various field equipment, such as pumps, solar chargers, and batteries to proactively identify potential operational issues. This system was designed to improve maintenance schedules and overall equipment reliability.

Key Contributions

Predictive Maintenance ML Solution

- Developed and deployed a machine learning model on AWS SageMaker to predict equipment malfunctions using sensor data.

- Utilized MLFlow and Metaflow for robust MLOps, managing the machine learning lifecycle from experimentation to deployment.

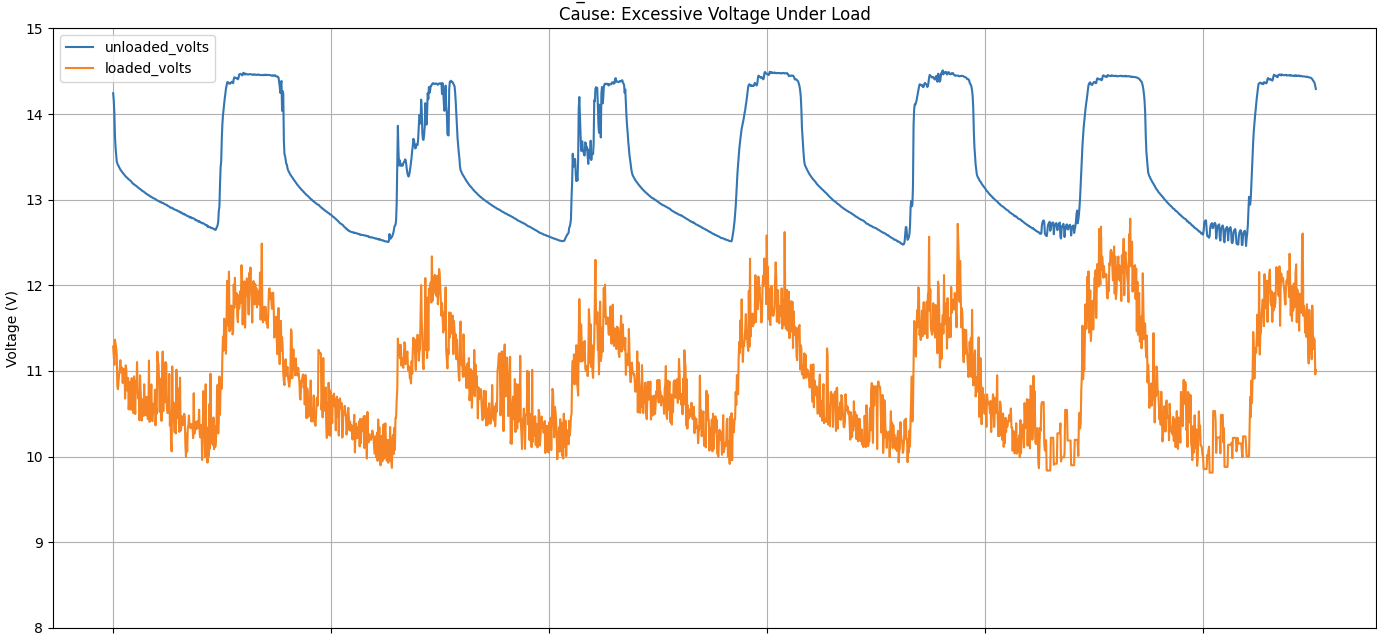

- Engineered features from sensor inputs to accurately detect anomalies and predict failures in equipment like pumps, solar chargers, and batteries.

Advanced Data Analytics & Integration

- Designed and implemented sophisticated analytics algorithms for processing and interpreting industrial IoT sensor data.

- Created real-time data processing pipelines for continuous monitoring and analysis within water wells, chemical tanks, and oil and gas operations.

- Ensured seamless integration of the ML solution with WellAware’s existing data infrastructure and sensor networks.

Operational Impact Focus

- Built predictive models specifically aimed at preventing equipment failure and minimizing downtime.

- Developed time series analysis solutions to optimize operational performance and resource allocation.

- Implemented automated alerting systems to notify stakeholders of critical operational parameters and predicted issues.

Impact

The predictive and reactive maintenance solution and enhanced analytics platform provided WellAware’s clients with significant improvements in operational efficiency. This was achieved through reduced equipment downtime, optimized maintenance schedules, and more informed decision-making capabilities driven by advanced data insights. The solutions contributed to optimizing systems operations while also helping to reduce operational costs.

Ready to Start Your AI Project?

Let's discuss how I can help transform your business with intelligent, scalable AI solutions like this one.

Schedule Your AI Consultation